Hydrostatic Extrusion

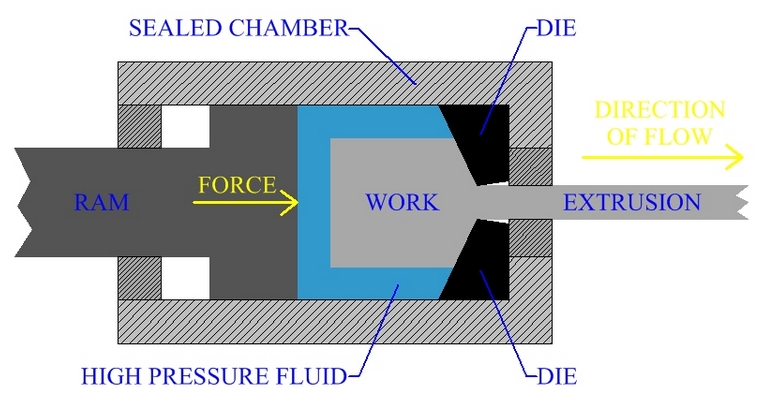

In the previous blogs on extrusion and its types- Direct extrusion & Indirect Extrusion, it was noted that the major drawback with direct extrusion is the frictional forces acting on the billet. Accordingly, one can either try backward extrusion or can move ahead with hydrostatic extrusion. Hydrostatic extrusion is basically type of direct extrusion, wherein the billet is confined in sealed chamber surrounded by pressurized fluid. The force delivered by the ram pressurizes this fluid, which further applies to the surfaces of billet. As the ram moves forward, it in effect applies force on the fluid, which causes displacement of billet through die, extruding the metal part.

The most important and complicated aspect of hydrostatic extrusion is its setup. In this process, the billet has to be first tapered so that it can fit through the die opening, thus forming a seal. This seal must be created before adding the liquid, so that it prevents the liquid from pouring out. In order to create the pressure within liquid, this seal must be precise enough to create a sturdy bond.

The fluid filled in the chamber can be pressurized in tow ways:

- Constant-rate Extrusion: The ram used can pressurize the fluid as it moves forward in the chamber.

- Constant-pressure extrusion: The fluid can be pressurized before it is pumped into chamber using a pump, like pressure intensifier.

Many different profiles can be extruded using hydrostatic extrusion using numerous materials. Different fluids can be used as mediums for hydrostatic extrusion including oils, melted polymers, waxes and molten glass. Owing to presence of fluid within, all the frictional forces inside the chamber are eliminated in this extrusion. Also, the hydrostatic pressure enhances the ductility of billet, thereby enabling brittle materials to be extruded easily. The liquid pressure from all sides also reduces greatly chances of buckling of work.

Hydrostatic extrusion can be performed at cold, room or even higher temperatures depending upon the manufacturing requirement. At elevated temperatures, the hot liquid would insulate the work from thermal gradients between the chamber and billet. In a more advanced form of hydrostatic extrusion called as fluid to fluid extrusion, the extruded part enters another chamber straight after extrusion, which contains liquid at a lesser pressure for further extrusion.

The major advantages of hydrostatic extrusion are as follows:

- The process goes at faster speeds, attaining higher reduction ratios at lower billet temperatures owing to lesser frictional forces between the chamber and the billet.

- An even flow of material is achieved thereby giving better surface finish.

- Larger billets and even large cross-sections can be extruded easily with this process.

- There is no billet residual at the chamber walls thereby achieving 100% extrusion.

Amongst all these advantages there are certain disadvantages including:

- The process can get complicated sometimes as the billet has to be tapered before process starts to make the seal. Also, in order to remove any surface defects, the entire billet needs to be wire-brushed or cleaned.

- Owing to complicated equipments and procedures, the process has longer cycle times.

- It sometimes gets difficult to contain the fluid under high pressure.

Bharat Industries with its 40 years of experience in Extrusion Process along with its extensive process understanding and system competence of our specialists, can provide you high-quality extrusion dies to achieve utmost results in direct extrusion.

This entry was posted on Wednesday, December 11th, 2013 at 7:17 pm and is belong to category Blog.