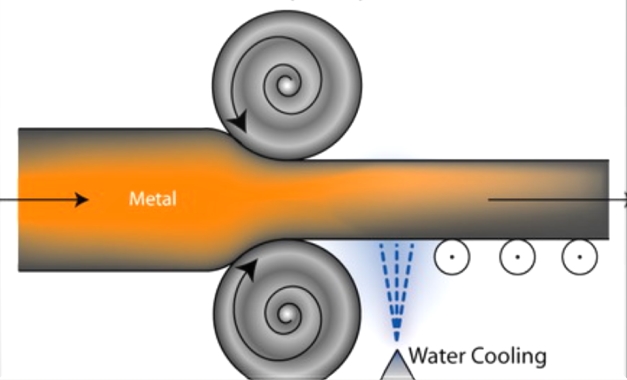

Cold Forming

Work Hardening also referred commonly as cold working or strain hardening process leads to strengthening of metal by its plastic deformation. The strengthening of metal is caused by the dislocation movements and dislocation generation occurring within the crystal structure of material. In metal-working processes, work-hardening stimulates plastic deformation to exact a shape change in metals. This is characterized by shaping the workpiece at temperature below its recrystallization temperature; usually at ambient temperature. At any time, the effects induced by work-hardening can be reversed by process called annealing carried at high temperatures, where recovery and recrystallization reduces the dislocation density.

Cold working can be applied to numerous non-brittle metals having high melting points as well as to several polymers to strengthen them. Other ,metal-alloys which cannot be amended by heat-treatment such as low carbon steel is also frequently hardened. Metals like copper and aluminum are most frequently work-hardened at normal temperatures.

Cold forming techniques are mostly classified into for major categories:

- Drawing

- Squeezing

- Shearing

- Bending

These applications generally produce final products like blots and screws and also finished cold rolled steel. Cold forming processes involve metal-working at high speed and high pressure using carbide dies or toll steel. Cold working is advantageous to metal-working as it increases the yield strength, hardness and tensile strength of work-piece. The further sections speak on the advantages as well as disadvantages of cold-forming process.

Advantages

- The very basic advantage of cold-forming is lack of heat treatment

- Cold working process enhances surface finish.

- Work-Hardening achieves better dimensional control.

- Better interchangeability and reproducibility.

- Cold-working also helps impart directional properties to the metal

- Since no heating or such processes are involved, cold-forming processes have least contamination problems.

- Cold forming increases strength to same degree as heat- treating and is much more economical.

- Mimimal waste occurs with cold-working as compared to machining and even eliminates with near net-shape methods.

- Lesser waste and nearly absence of contamination achieved by cold-forming adds greatly to savings when working with large volumes and even more with expensive metals like copper.

- Last but not least, cold-working process have very small production cycle times.

Disadvantages:

Cold working causes work-hardening and the work-piece microstructure deforms to follow the contour of part-surface. However, this leads to anisotropic changes in material properties greatly due to distortion followed along the surface-curve by the inclusions and grains.

Other major disadvantages include:

- In cold-working, greater forces are required to attain hardening of work-piece.

- Owing to high force requirement, heavier and much powerful equipment are needed.

- Cold-formed metals are lesser ductile as compared to heat-treating.

- Cold forming processes need to be processed before for cleaning and to make them scale-free.

- In certain cases, intermediate annealing is also needed to balance the loss of ductility caused by strain-hardening, otherwise the material may fracture owing to exceeding of its tensile strength.

- The directional properties imparted by cold-forming ca sometimes be damaging.

- In certain cases, undesirable residual stress can also be produced.

- Due to need of heavier machineries, large capital costs are need for cold working process making it favorable only for large volume productions.

- Cold working also leads to phenomenon called as springback or elastic springback. The material springs back slightly sometimes after removal of deforming force, known as springback. The amount a material springs back is equal to the yield strain (the strain at the yield point) for the material.

This entry was posted on Sunday, December 29th, 2013 at 1:28 pm and is belong to category Blog.